Confectionery Products

Classification of Confectionery

- Sugar confectionery

- Chocolate confectionery

- Flour confectionery

- Milk-based confectionery

- Sugar Confectionery Groups

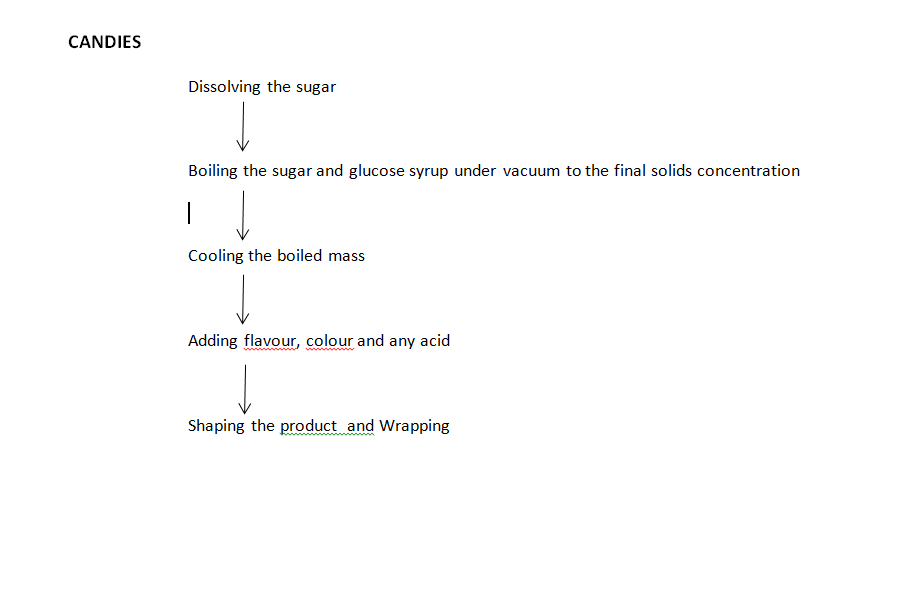

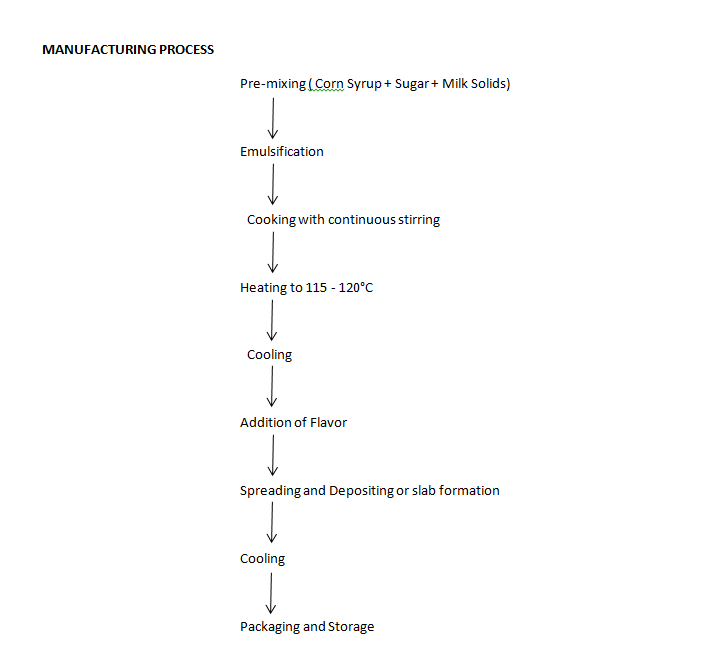

- Amorphous sugar confectionery – hard boiled candy, caramels, toffee, gums, jellies, etc etc

- Crystalline sugar confectionery – chocolate, nougats, fudge etc etc

Major Raw material for Sugar Confectionery –

- Sucrose And Its Derivatives

- Glucose Syrups, Sugars And Other Sweeteners

- Fats

- Milk Products

- Foaming Agents

- Gelling Agents , Thickeners And Stabilizers,

- Colors

- Flavors

- Acids

- Nuts And Some Processing Aids.