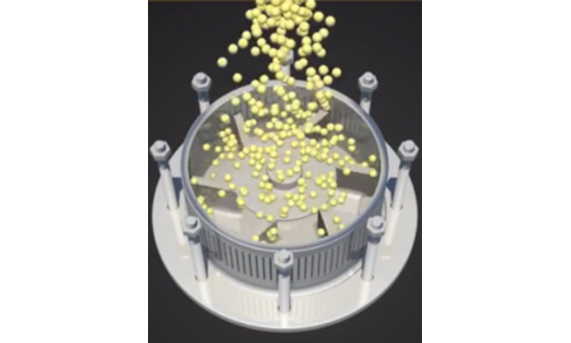

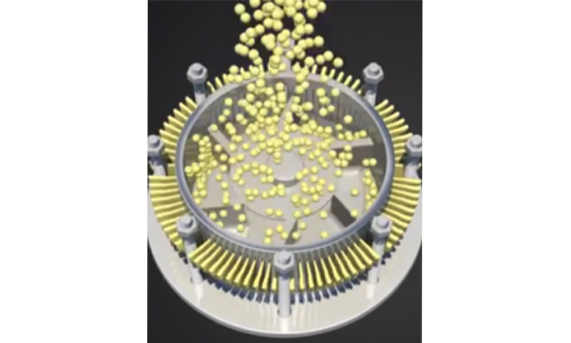

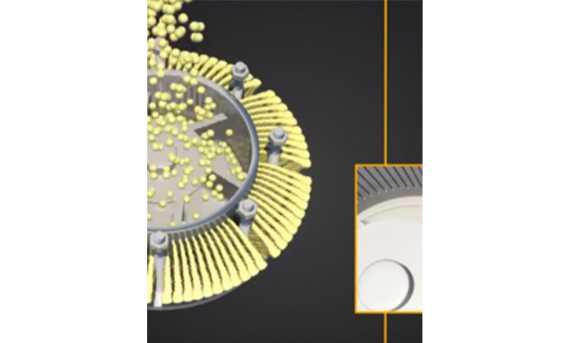

High shear homogenizer mounted at the bottom is used to disperse immiscible liquids, solid in liquids, preparing homogeneous slurries and powder dissolution in liquids for complete batch.

Bottom mounted homogenizer also commonly known bottom entry mixer. The major application of bottom homogenizer is emulsification, blending, dissolution of solids into the liquids as desired by the application. The working head, i.e., the rotor/stator breaks down hard solids into fine particles. The bottom entry mounted homogenizers are best suitable for dis-integrating, dissolving, solubilizing, and dispersing solid in the liquids and can accommodate harder solids into the liquids/solutions as desired by the application.

The bottom drive is mounted on the bottom of the vessel with the working head (rotor & stator) dipping in the material being processed. The homogenizer is responsible for dis-integrating solids in the liquid and break huge blocks/bricks/agglomerates present into fine particles to ease the dissolving of the solids in the liquids. The solids are literally ripped apart into fine particles and are easily dispersed into the mix.