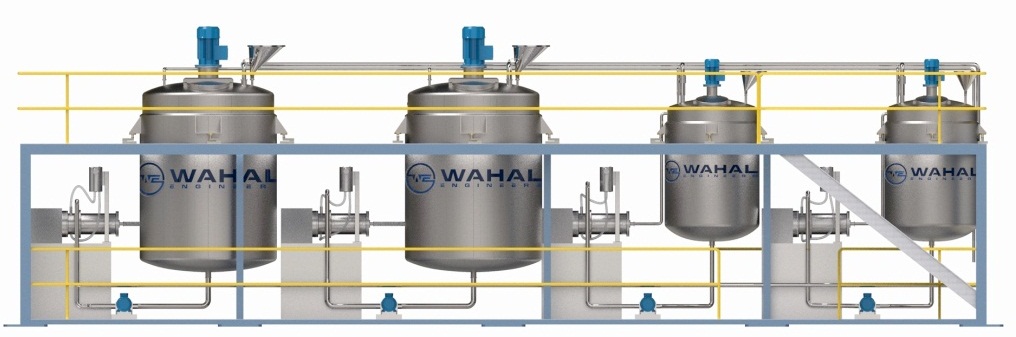

Lube oil blending plant

Lube oil processing involves various stages to produce high-quality lubricating oils, and Wahal high shear mixers play a crucial role in some of these processes. Wahal High shear mixers are designed to break down and disperse particles in fluids, creating a homogenous mixture. Here’s a general overview of how high shear mixers can be used in lube oil processing:

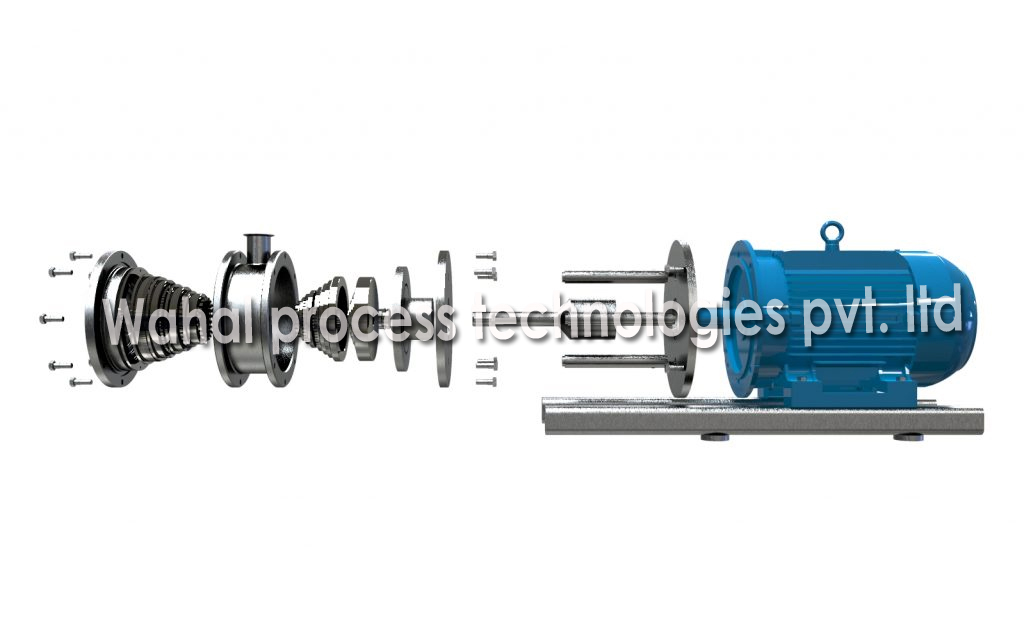

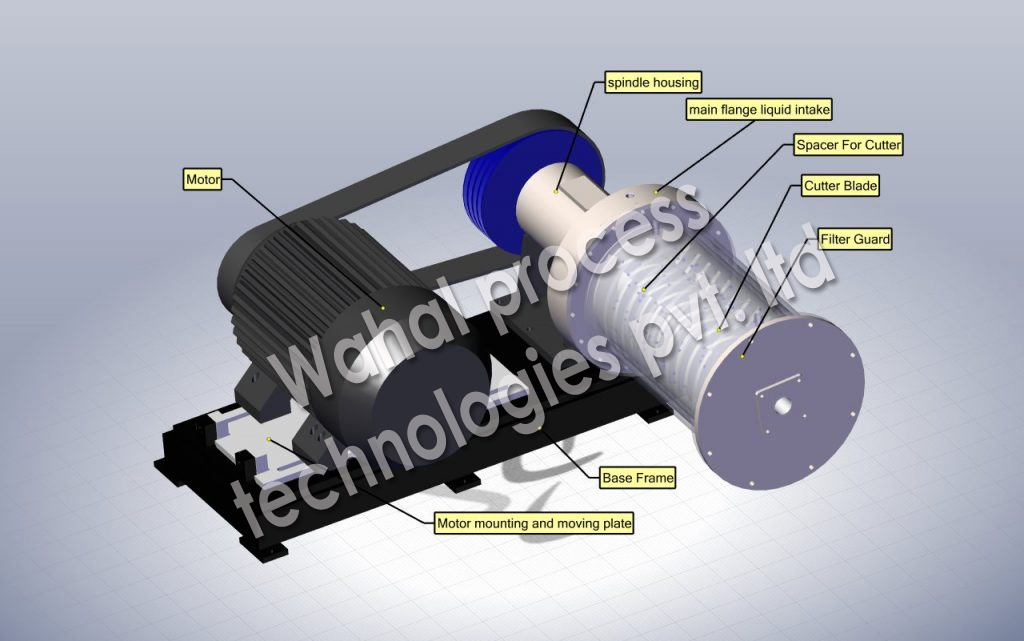

Bottom mounted homogenizer also commonly known bottom entry mixer. The major application of bottom homogenizer is emulsification, blending, dissolution of solids into the liquids as desired by the application. The working head, i.e., the rotor/stator breaks down hard solids into fine particles. The bottom entry mounted homogenizers are best suitable for dis-integrating, dissolving, solubilizing, and dispersing solid in the liquids and can accommodate harder solids into the liquids/solutions as desired by the application.