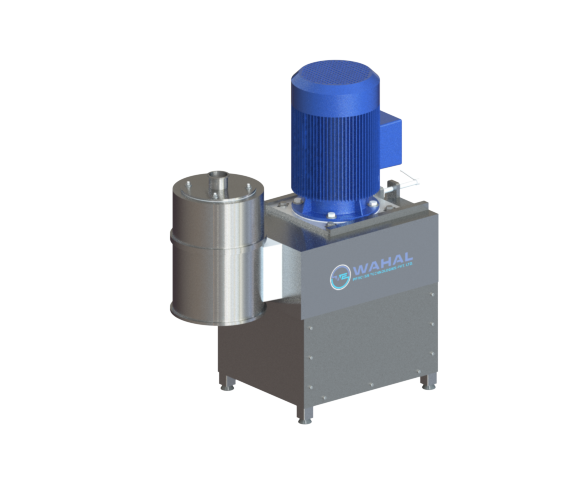

Wahal’s Multi processor is the latest machine for the very fine cutting of all types of fine food products without any distractive heat. The main Motor with IP-55 class is comprised with a fitted brake which can stop the rotor from very high speed and fitted on top of the stainless steel table along with spindle assy.

Rotor shaft Is driven through a special tension/ maintance free and power efficient sandwich belt with very high precision bearings with special sealing/ lubrication arrangement. The whole system is based on Rotor/Stator technology, where a precision rotor with close clearance rotate in very fine slotted head stator at very high speed of up to 12,000 RPM.

Material can be pumped through a suitable pump with control form or either to be fed manually through a hopper/ funnel where flow could be controlled through a ball valve. For better results one can employ our In Tank Homogenizer for small batches for the Pre-mixing of liquids and powders or initial crushing of fruits/vegetables.