- Liquid ingredients are weighed and metered into the process vessel. Heating follows to aid the melting of the fat, dissolving, and hydration of the subsequent ingredients.

- Powdered ingredients such as skim milk powder, sugars, whey powder, and more are added to the liquid and mixed until appropriately dispersed.

- Then the stabilizing and emulsifying agents are added. These may be dry premixed with the other ingredients, including sugar, to decrease particle agglomeration and further “weight” the powder to incorporate the liquid.

- Then the fat is added. But before that, butter or other solid fats are melted in a separate vessel.

- Then the mix is pasteurized at 185ºF (85ºC).

- The mix is then homogenized, usually by passing through a high-pressure homogenizer.

- The product is then “aged” into a holding or ripening tank allowing the stabilizing agents to hydrate and the fat to crystallize.

- Flavour and coloring can be added at this particular stage.

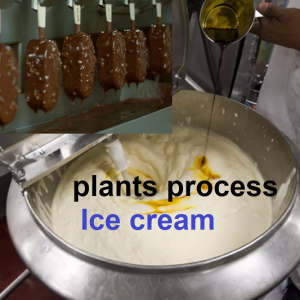

- The finished mix is then frozen in special freezers, which whip a controlled amount of air into the mix.

In many countries, the legislation covers the composition and labeling of products. These regulations restrict the user to particular ingredients and specify the minimum content of the fat and total solids to be used.

WHAT OUR CLIENTS SAY

Testimonial

Give us a call or drop by anytime, we endeavour to answer all enquiries within 24 hours on business days. We will be happy to answer your questions.

Contact:

Mr. Shubham : +(91)-9899387031

Head Office

Plot No. G-39, Friends Industries Area, Shahbad, Daulatpur

New Delhi – 110042, Delhi, India