For the development of each nation, road network plays a very important role. Developed nation pays the cost of the effect of environmental conditions which is very harmful for human aspects. That’s why, there is great need for sustainable development for the preservation of environmental conditions. Many countries, including India, introduced Bitumen is used as a binder constituent in road construction. For reducing pollution and the heating effect, cold mix technology (type of bitumen) is used.

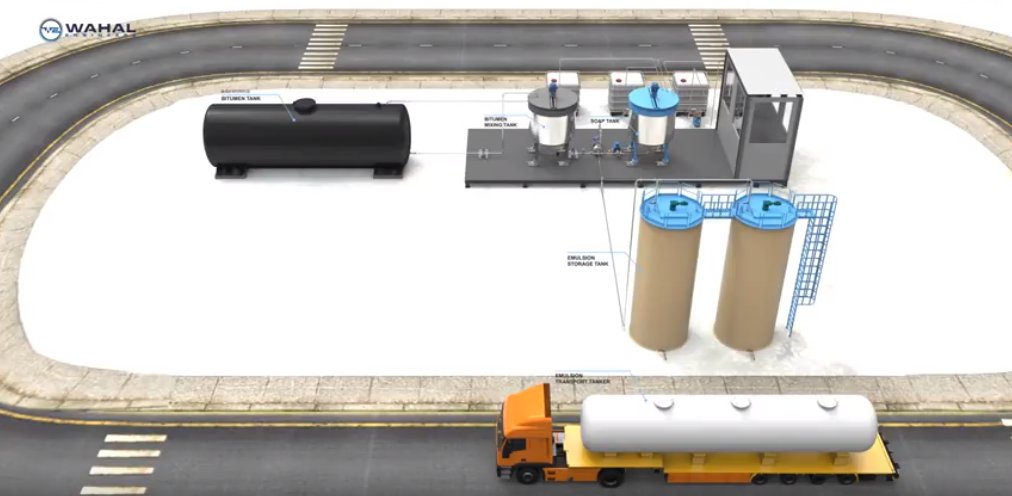

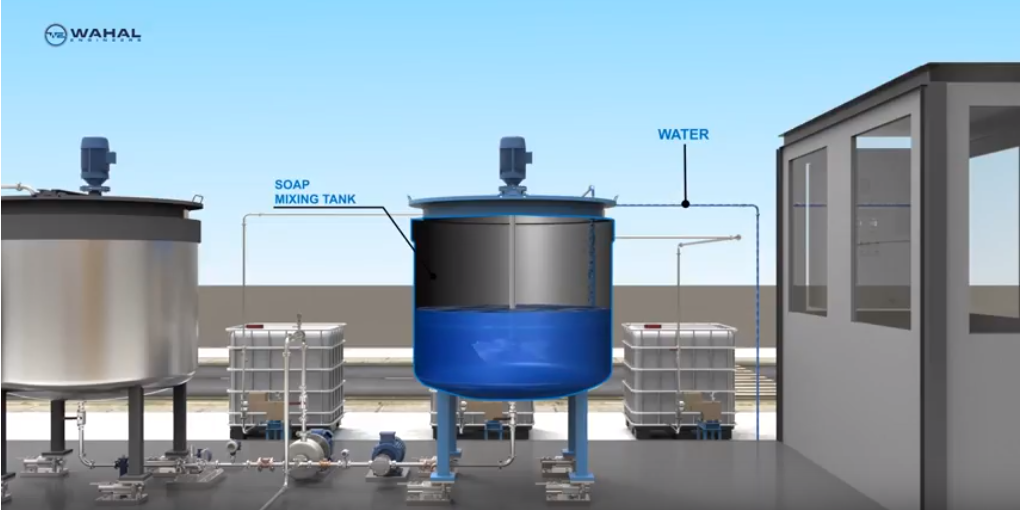

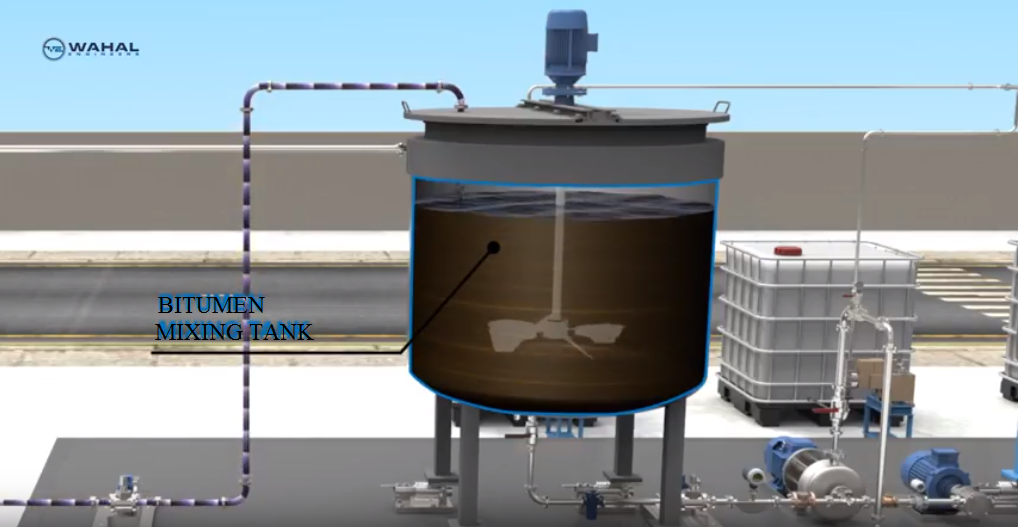

In cold mix technology, bitumen are used to aggregate in the road making process is in the form of a so-called “bitumen emulsion”. It is an emulsion liquid product of water and bitumen in which bitumen fine droplets are suspended in aqueous solution. Bitumen is a by-product of petroleum and it does not mix with water, so we are adding an emulsifier with water after that bitumen is added.

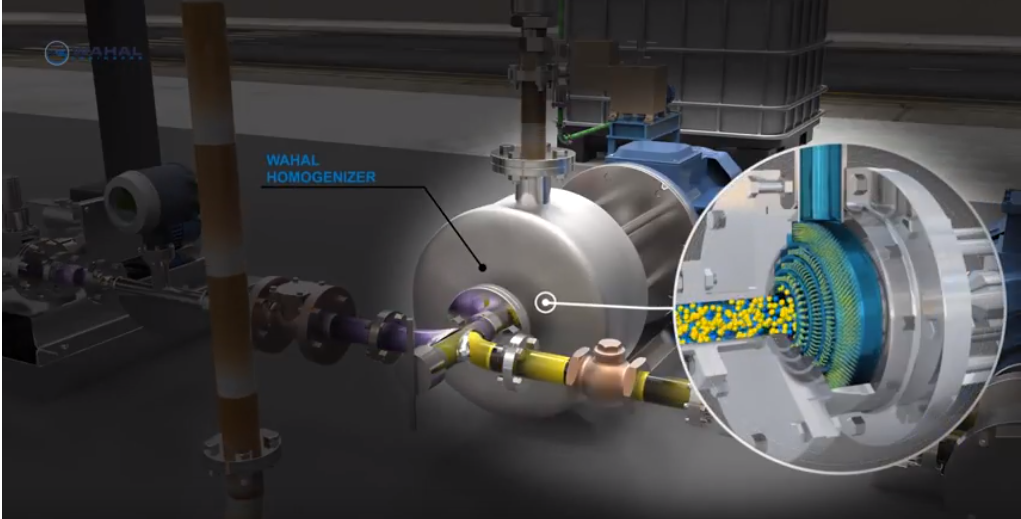

The emulsifier is breaking down the bitumen into minute particles and keeps its suspension. Bitumen emulsion liquid consisting 3 things, i.e, water, emulsion and bitumen.