Resin Chemical Equipment

https://wahalengineers.com/powder-induction-mixer/

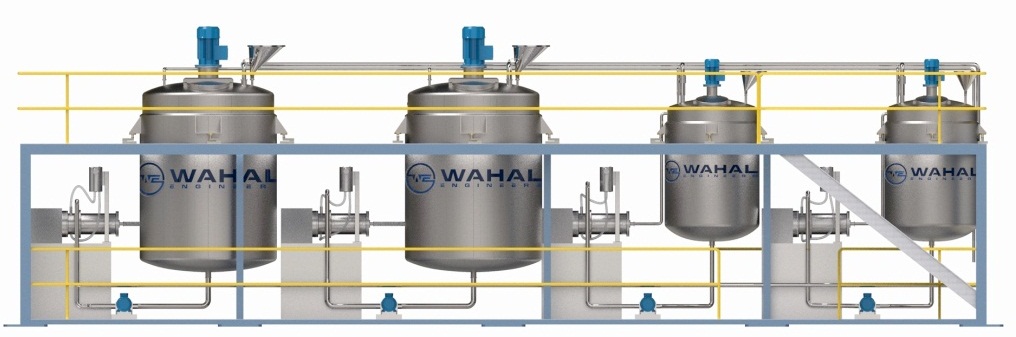

Resin equipment is a type of industrial equipment that is both practical and productive. It is widely used in various parts of the country and has great demand on the market. Our company is one of the most reputable companies, offering some of the best industrial chemical processing equipment to our customers, and hence our company has also designed these resin plants brilliantly. These resin plants are widely used in the production of various industrial paints, emulsions, and coatings. Complete services, including delivery and installation, are available in nearly every region of the country.These chemical plants are specially designed to process and produce all types of chemicals needed for industrial processes. These chemical plants are used and loved in almost all parts of the country and are widely demanded in various chemical and pharmaceutical industries.

Features:

- Excellent construction

- Reliable and safe to use

- Durable

- Low consumption

- Low maintenance

- Affordable

Specifications:

- Material:

- Size:

Alkyd Resin Factory Specification

It is a 5000-liter resin equipment; each batch can produce 10 tonnes. It mainly includes a 5000L reactor and a 10000L dilution boiler. It has several heating methods, including coal, natural gas, and diesel. The electrical heating method for 10-ton/day equipment is as follows:

Equipment and Alkyd Resin Reactor Configuration of a 5000-L Resin Reactor:

- Inner wall material and thickness: 304 stainless steel plate, 4 mm

- Material and thickness: carbon steel, 8 mmMixing tube: 11-kw motor, 4-lb. cycloid reducer, 85 R.P.M.

- Mechanical seal

- Electric heater: 5 kW at 18 volts

- Automatic temperature control, with power card

- Vertical condenser: 5 square metres

- Horizontal condenser: 20 square metres

- Separation column diameter: 280 mm, height: 1000 mm, one elbow

- 8 rings (304 stainless steel); 50 inner baffle pipe

- Oil-water separator: 304 stainless steel 300L

- Q235 carbon steel buffer tank 500-10,000 litre fine pot material configuration

- Thickness of steel and stainless steel: 10mm

- External material and thickness: carbon steel, 8 mm;

- Tube mixer motor: 15 kW, 5 HP cycloid reducer, 85 R.P.M.

Polyester resin plant

Application

1). Resin: alkyd resin, epoxy resin, phenolic resin, acrylic resin, unsaturated polyester resin, polymer resin.

2). Colle/colle: colle/colle thermofusible, colle blanche, colle silicone, colle PVC, PVA, and colle PU.

3) Other: Paints, pigments, other latexes, emulsions, and liquid adhesives and glues