Demystifying the Challenges of Mixing CMC and Carbopol: Harnessing the Power of High Shear Homogenizers

Introduction

The process of mixing CMC (Carboxymethylcellulose) and Carbopol can pose significant challenges due to the nature of these materials. However, high shear homogenizers have emerged as reliable machines capable of overcoming these difficulties. In this article, we will explore why mixing CMC and Carbopol can be challenging, the benefits of using high shear homogenizers for dispersion and emulsification, and the industries that extensively utilize CMCs in their applications.

The Challenges of Mixing CMC and Carbopol

Mixing CMC and Carbopol can be challenging due to the following reasons:

- High Viscosity: Both CMC and Carbopol exhibit high viscosity, making it difficult to achieve uniform dispersion and prevent clumping. Traditional mixing methods often struggle to break down agglomerates and disperse these materials effectively.

- Shear Sensitivity: CMC and Carbopol are sensitive to shear forces, which can lead to the degradation of their properties. Inadequate mixing techniques may result in altered rheological behavior and reduced functionality of the final product.

- Hydration Time: CMC and Carbopol typically require sufficient hydration time to reach their full viscosity and gel-like consistency. Inefficient mixing processes may lead to incomplete hydration, resulting in poor quality products and inconsistencies in performance.

High Shear Homogenizers: The Solution

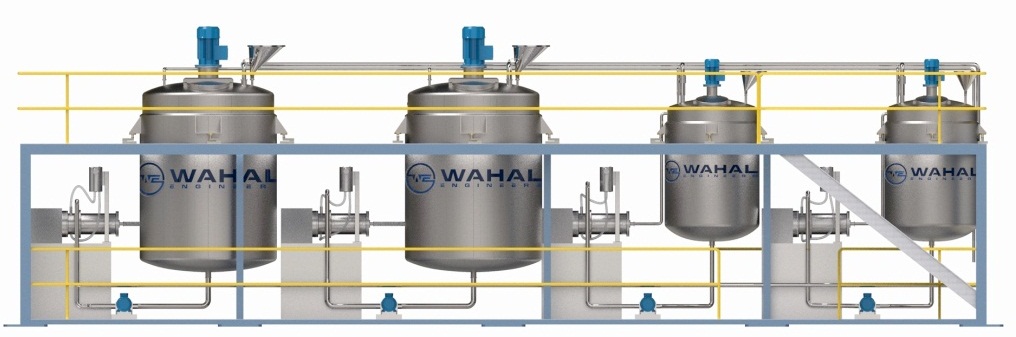

High shear homogenizers have emerged as reliable machines for addressing the challenges associated with mixing CMC and Carbopol. These homogenizers offer several advantages:

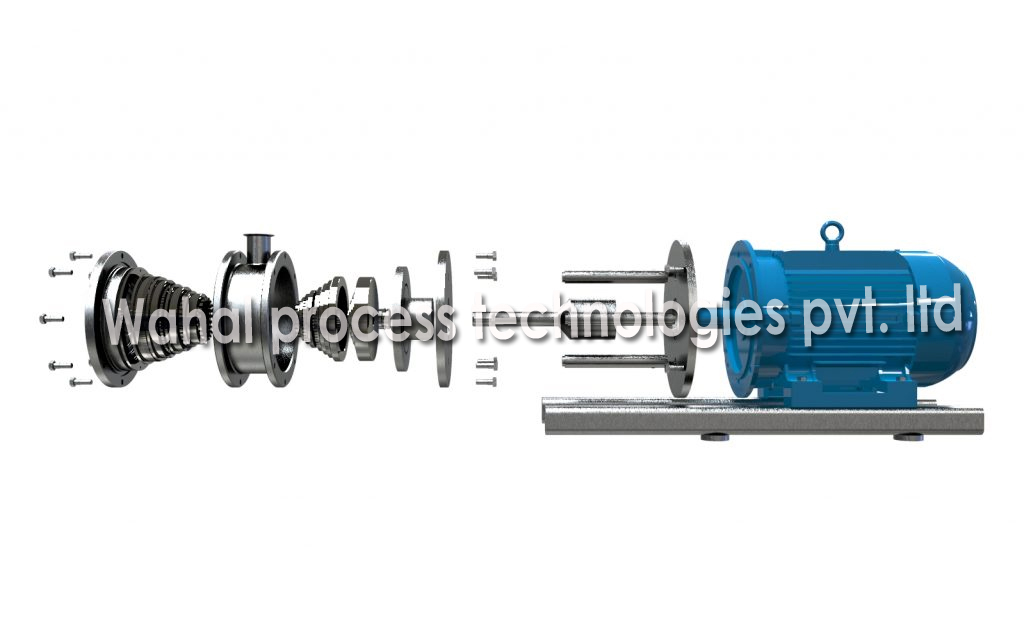

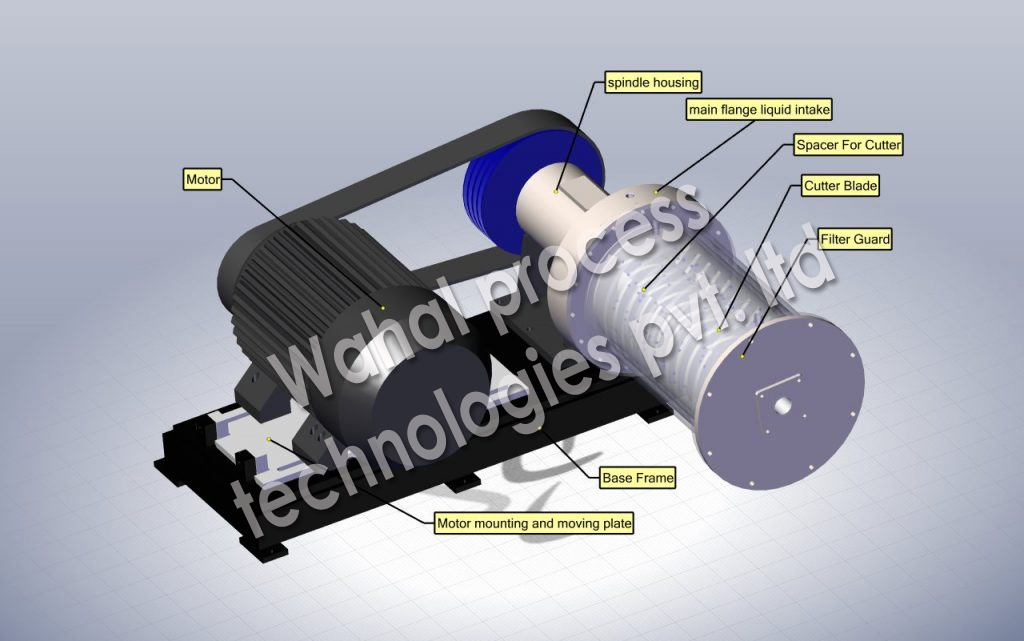

- Dispersion and Emulsification: High shear homogenizers utilize intense mechanical forces to disperse and emulsify materials effectively. The high rotational speed and specialized rotor-stator design generate powerful shear forces, breaking down agglomerates and promoting uniform dispersion of CMC and Carbopol.

- Reduced Processing Times: High shear homogenizers significantly reduce processing times compared to conventional mixing methods. The intense shear forces generated by these machines accelerate the dispersion process, allowing for faster and more efficient mixing.

- Precise Control: High shear homogenizers provide precise control over the mixing parameters, such as rotational speed and shear intensity. This control allows for customization based on the specific requirements of CMC and Carbopol, ensuring optimal dispersion and avoiding excessive shear.

- Enhanced Product Quality: The efficient dispersion achieved by high shear homogenizers results in improved product quality. These homogenizers can break down particles to submicron sizes, leading to smoother textures, enhanced stability, and improved overall performance of the final product.