Ragi and Millet based Ready to eat foods instant mixes plant

1. Raw Material Selection & Cleaning

Millets Used: Finger millet (ragi), pearl millet (bajra), foxtail millet, little millet,

barnyard millet, etc.

Additional Ingredients: Pulses (urad dal, moong dal), rice, spices, dried herbs, salt,

etc.

Cleaning Process:

o Destoning

o Sieving

o Aspirating (for dust and husk removal)

o Washing (if wet processing is used)

2. Roasting or Pre-cooking

Purpose: Enhance flavor, reduce anti-nutrients, increase digestibility, and extend shelf

life.

Methods:

o Dry roasting in rotary roasters or fluidized bed roasters

o Steam cooking or blanching followed by drying for instant porridge mixes

3. Drying (if pre-cooked)

Equipment: Tray dryers, rotary dryers, or hot air ovens

Ensures final moisture content is below ~10% to improve shelf life.

- Grinding / Pulverizing

- Equipment: Hammer mills, pin mills, or pulverizers

- Output: Fine flour or granular blends depending on the product (porridge mix vs upma mix)

- Blending

- Millets are mixed with other dry ingredients for preparing instant mix like:

- Pulses flour

- Spices and condiments

- Salt or sugar

- Natural stabilizers or binding agents (if needed)

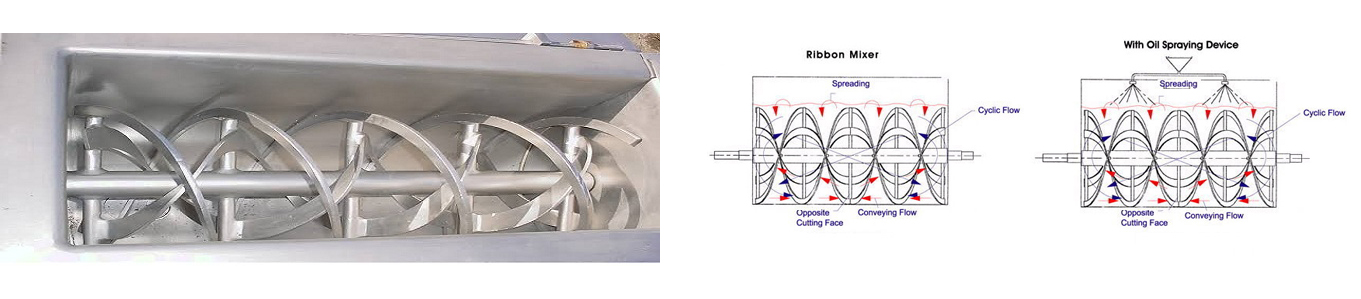

Equipment: Ribbon blender, paddle mixer, or conical blender